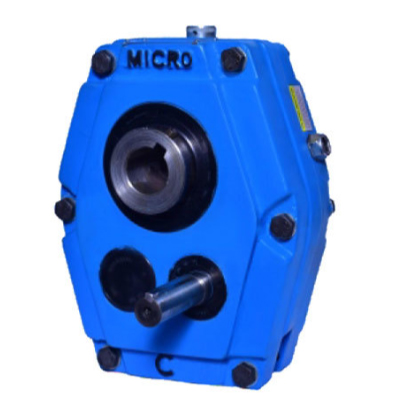

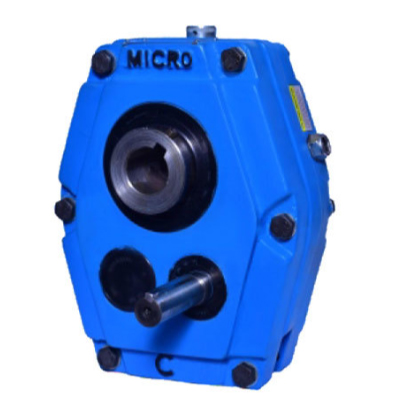

MICRO Shaft mounted speed reducers are compact and metric in design throughout and conforms to international standards. MICRO shaft mounted speed reducer provides a very convenient method of reducing speed, since it mounted directly on the drive shaft instead of requiring foundation of its own.

A direct mounting attribute ensures positive and permanent alignment of the gear reducer and permits convenient location of the motor and eliminates the use of Couplings, Chain Wheel or Pulley. It is also minimize the space requirements and layout problems. A torque arm (tie rod) anchors the gear reducer and provides quick, easy adjustment of the V Belts by means of its turnbuckle.

Shaft Mounted Speed Reducers designed to meet any position requirements and provides wide range of output speed and it is suitable for both forward and reverse motion.

MICRO Shaft Mounted Speed Reducers are manufactured in seven gear case sizes, designated by the letters C to J. The all seven sizes may have four nominal gear ratios 05:1, 13:1, 20:1 and 25:1.

A very wide range of final driven speed may be achieved by the use of an appropriate input V-Belt drive through various pulley combinations. All gear reducers will normally splash oil lubricated.

A backstop is the additional feature which let the reducer turn freely in one direction but locks up when reversed. This is required on applications such as belt conveyors or bucket elevators to prevent injury if electrical power to the motor is interrupted. Holdback/Backstops are designed and incorporated to prevent reversal rotation or holding device to prevent reverse rotation in application such as Conveyors, Bucket Elevators, Fan and Rotary Kilns.

Major Benefits

Savings of Time and Labor because it eliminates cleaning of conveyor belt during closing of conveyor or whole plant.

Motor Mounting Frame options are available to fit directly on the top of gear reducers through special designed Motor Mounting Frame accessories for the Shaft Mounted Speed Reducers. Motor Mounting Frame accessories are developed with robust base plate which allows wide range of motor frame sizes.

Every Motor Mounting Frame has sufficient adjustment to ensure that belt can be fitted and tensioned whenever required throughout life of belts.

Major Benefits

The Motor Mounting Advantage facilitates the direct mounting of motor at input side and eliminates the extra foundation, pulley, couplings or any other accessories. The Motor Mounting Reducers are specially designated for the Screw Conveyors.

Main Advantage of this feature is that no need of any alignment due to its character of directly fitting in to the reducer's shaft so it's fixes the all alignment errors.

Major Benefits

Savings of Time and Labor because it eliminates cleaning of conveyor belt during closing of conveyor or whole plant.

Taper Lock Bush allows unskilled labor to achieve coupling of reducer and shrink fit on shafts using just hexagon wrench. Taper Lock Bushing Accessories has arrangement of longitudinal split tapered bushes with four through all holes, two threaded holes and four threaded holes on the reducer's output hub.

Taper Lock Bush and Reducer's Output Hub are manufactured from special steel to permanently remove any chances of corrosion in the future. The unique Taper Lock Bush system, which overcomes the difficulties, experienced with other methods of mounting, particularly in corrosive environment. Various sizes of Bores are available in the Taper Lock Bush to facilitate easy mounting on different shaft size.

So any labor can install the reducer by just tightening of four Allen Key Bolts, and uninstall by just tightening of two Allen Key Bolts. That give easy, fast fitting and maximum grip. (Taper Lock Bush and Reducer's Output Hub must be tight to gather).

Major Benefits

There are some range of extra accessories developed with their own advantages for Shaft Mounted Speed Reducers according to purposes, fitment and application of the machine in order to fix the errors, and easy motion of the machinery.

Tags: Shaft Mounted Speed Reducer Manufacturer in Mumbai, Shaft Mounted Speed Reducer Manufacturer in Delhi, Shaft Mounted Speed Reducer Manufacturer in Bangalore, Shaft Mounted Speed Reducer Manufacturer in Hyderabad, Shaft Mounted Speed Reducer Manufacturer in Ahmedabad, Shaft Mounted Speed Reducer Manufacturer in Chennai, Shaft Mounted Speed Reducer Manufacturer in Surat, Shaft Mounted Speed Reducer Manufacturer in Pune, Shaft Mounted Speed Reducer Manufacturer in Jaipur, Shaft Mounted Speed Reducer Manufacturer in Kanpur, Shaft Mounted Speed Reducer Manufacturer in Nagpur, Shaft Mounted Speed Reducer Manufacturer in Indore, Shaft Mounted Speed Reducer Manufacturer in Bhopal, Shaft Mounted Speed Reducer Manufacturer in Patna, Shaft Mounted Speed Reducer Manufacturer in Vadodara, Shaft Mounted Speed Reducer Manufacturer in Nashik.

All Copyrights © 2025 Micro Precision Works || Shaft Mounted Gearbox Manufacturer

Designed and SEO Manage by : :